EMS & Custom Power Modules

- ISO 6 Clean Room

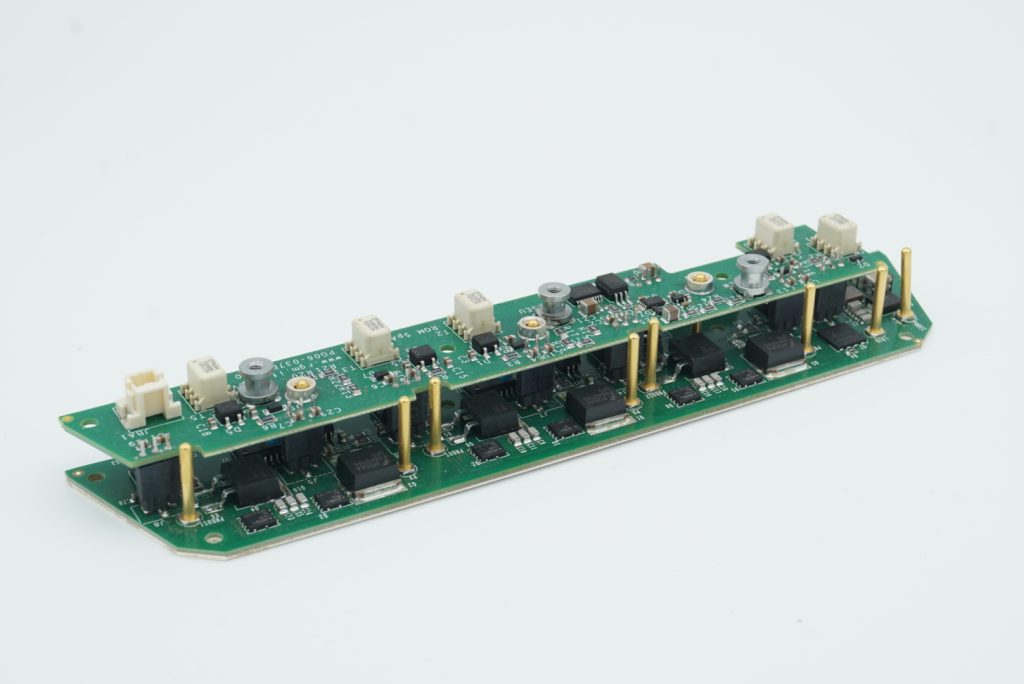

- Assembling of electronic boards in SMT and PTH technology

- 3D Optical inspection

- X-ray Inspection

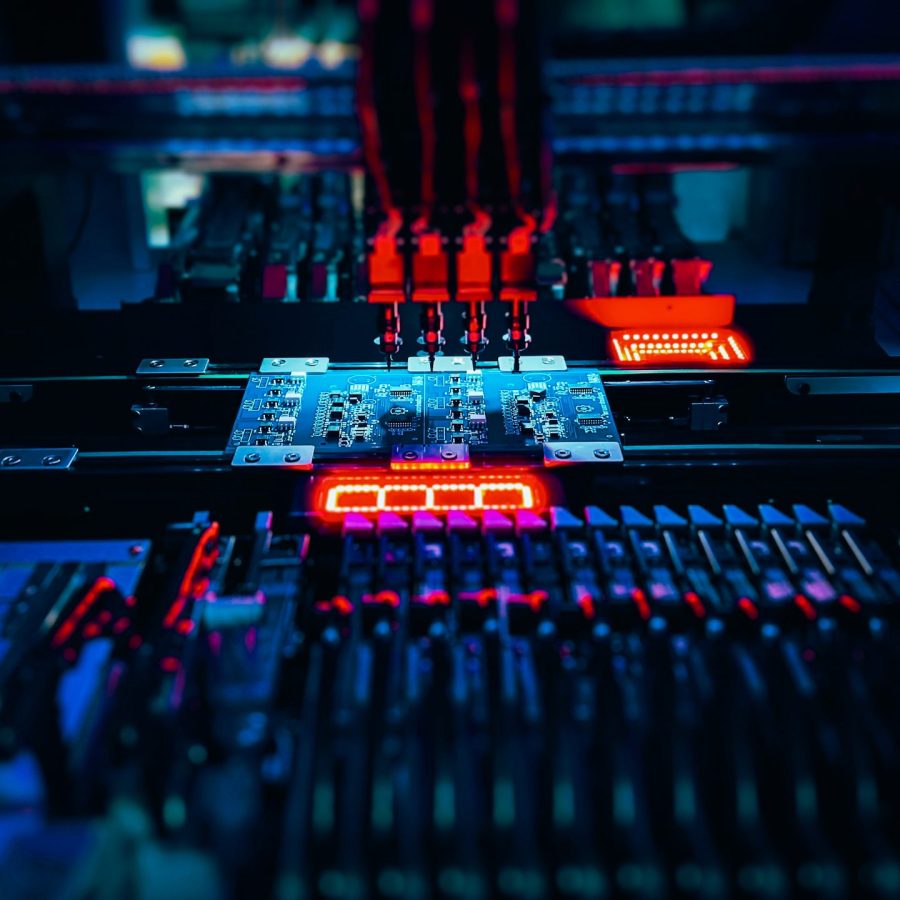

- Functional and In-circuit tests

- Burn-In

- Potting and conformal coating service

- Reworking and finishing service

High quality services with best-in-class equipments

Engineering

Full development of PCB and hybrid power modules

Traceability

Long-term storage of data traceability with MYTrace software

Prototyping & Mass Production

Fast and reliable services with dedicated supply chain

Testing

The best testing equipment to ensure quality and reliability.

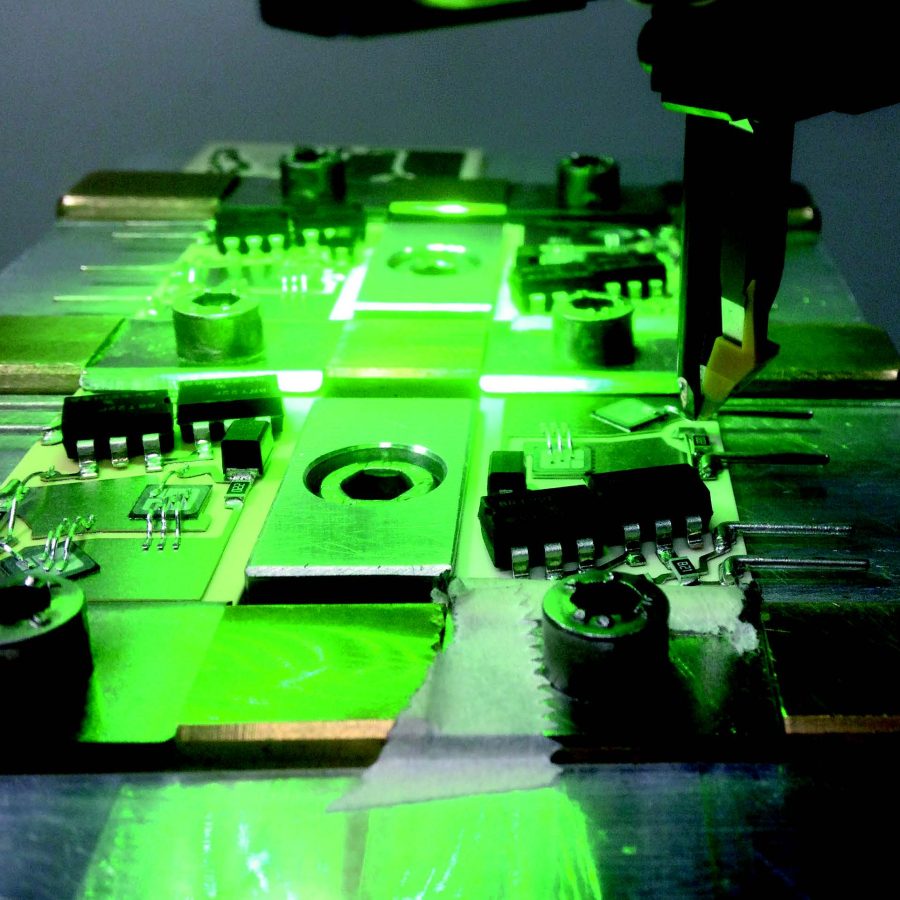

Wire Bonding Technology

RGM projects, develops and produces hybrid power modules using several substrates, such as IMS, DCB (both in alluminium oxyde and alluminium nitride), and baseplates in alluminium, copper and AlSiC. This technology uses diodes, SCRs, Mosfets and IGBT in die.

Orthodyne M3600, in combination with Vapor Phase Oven VP 6000, allows RGM to create products at the higher quality level, performing tests even during the assembly (i.e. pull test).

ISO 6 Clean Room Certified

The clean room, dedicated to the realisation of Hi-Rel applications, is certified under ISO 6 class at the operational state.

Operators are trained and equipped with thebreakthrough materials and documentations to provide the best in class service.

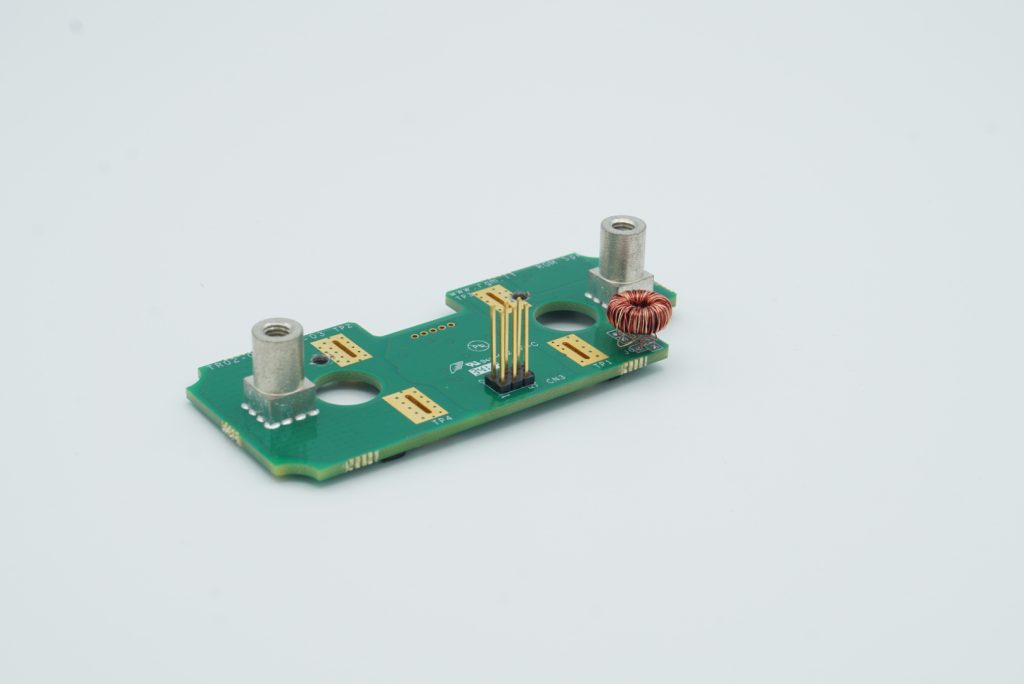

Custom Power Modules

Power Module

Static Switch + Ideal Diode

150 A, 48 VDC

Power Module

Solid State Relay

3PHASE SCR Module

Up to ASA – 600 VAC

Power Module

Static Switch

PCB in SMT – THT Technologies